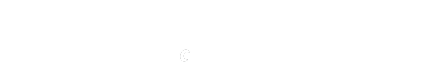

MATERIAL PROPERTIES

Influence of elements in steel chemistry

C:

Carbon is the most relevant element to control hardness charateristics, it is necessary to guarantee the correct martensitic tansformation.

Caution:

High C rate can lead to reduced toughness and is the principal cause of brittleness.

High C rate can give final undesired metallic structures leading to lack of wear resistance

High C rate is responsible of thermal shock sensibility and heating cracks propagation.

Cr:

Chromium carbides increase wear resistance, evenly increase the hardenability, break corrosion phenomena at high temperature, decarburization and oxides, increase mechanical characteristics at high temperature conditions, improve polishability.

Mo:

Molybdenum is responsible for steel hardenability, increases surface hardening depth because it decreases the critical cooling rate, guarantees uniformity for cross-section hardness, helps to keep small the austenitic grain during heating leading to fine martensitic structure.

V:

Vanadium is responsible for high yield strength and elongation and increases compressive strength, giving steel the best toughness and shock resistance cababilities; further increases wear resistance and helps to guarantee low grain size after hardening.

Ni:

Nickel increases the mechanical characteristic leading to high tensile strength meterials, slightly helps hardenability and increases impact strength.

CHROMIUM:

MOLYBDENUM: