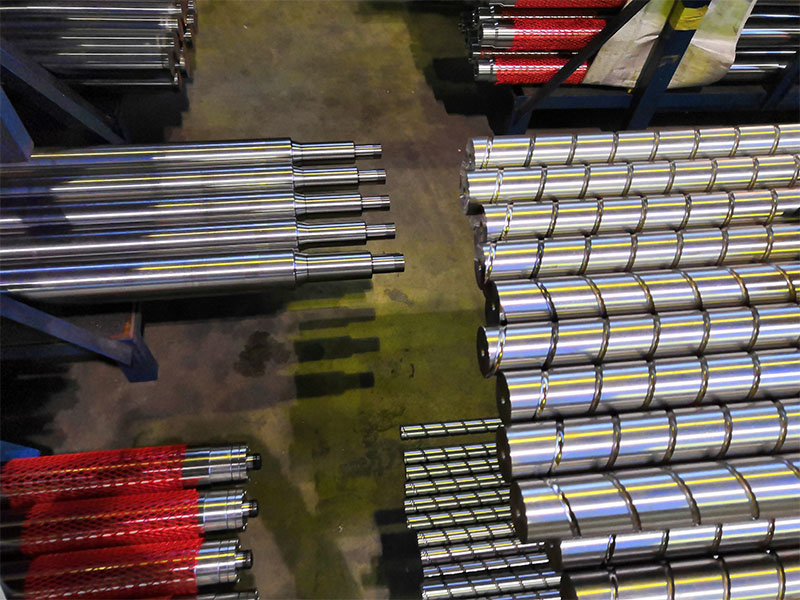

All the products of BSA are finished by grinding with top quality surface conditions.

We define and optimize the performance of the rolls and components taking care of surface finishing parameters. Process control techniques and our internal manufacturing technology enable us to produce according to customer expectations, ensuring performance and uniformity of the surface of the rolls.

The rolls’ surface finishing is related to the roll working attitude considering material roughness and conditions of the sheet to be processed.

Ground Surface Finish – this is the rolls normal finishing condition that consist of roughness between Ra 0.4÷0.8 µm. This finishing is used for all rolls over diameter 150 mm.

Polished Surface Finish – this is the rolls normal finishing condition that consist of roughness between Ra 0.2÷0.4 µm. This finishing is used for all rolls below diameter 150 mm.

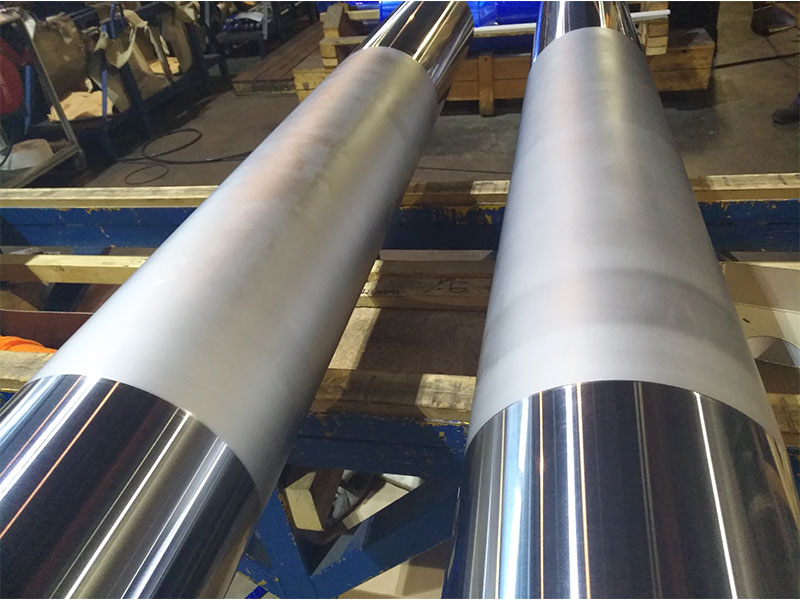

Mirror Polished Surface Finish - Rolls with a mirror finish are very smooth. The rolls are shiny and reflective. The surface finish typically is specified to Ra 0.05÷0.2 µm. This finishing is made under specific request and mostly used for rolls operating with non ferrous metals or bright stainless steels.

Chrome coated Surface Finish - Optical finishes are flawless, mirror reflections. Rolls with chrome coating are used to manufacture precision thin hard foil/coil and in line with a high rolls corrosion. The surface finish is measured below Ra 0.25 µm max. The Chrome layer give a higher hardness, better wear resistance and also guarantee corrosion resistance. Optimal finish condition for wet levellers.

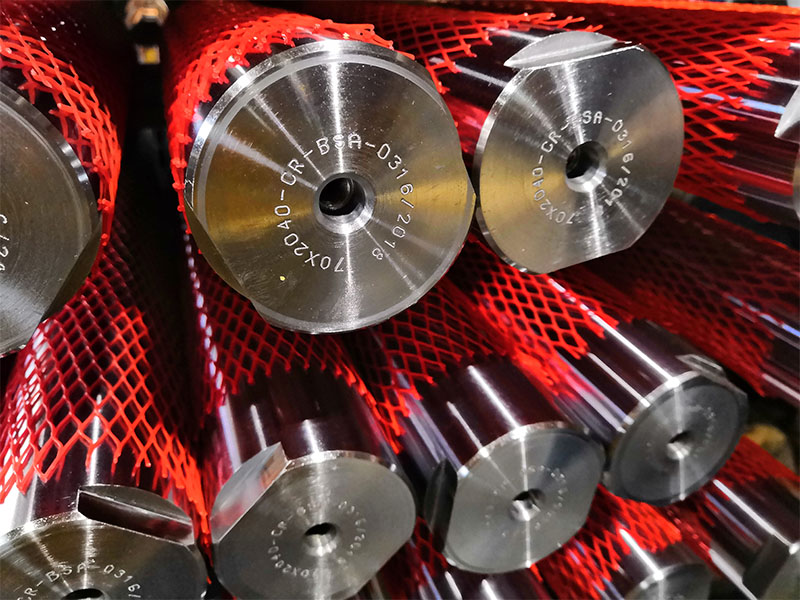

Sand blasted and Chrome coated Surface Finish – Developed to increase the material grip, this finished textured surface is generated by sand blasting. Rolls with these finishes allow the coil not to slip to the roll surfaces. The surface roughness can be adjusted according to customer request, usually between Ra 1÷2.5 µm. The Chrome layer gives a higher hardness and guarantees corrosion resistance. Optimal finish condition for pinch rolls and feeder for presses in blanking lines.