Old tension levelling equipment engineered for rolling mill materials can require an upgrade of performances to process new high tensile strength materials.

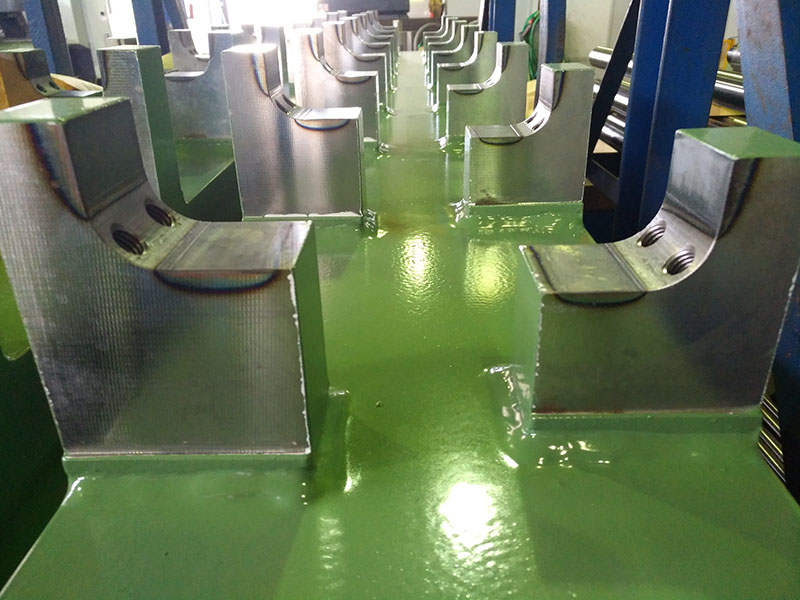

Thanks to our experience we can offer upgrade solutions to increase and optimize cassettes dynamic load properties by adding new components and taking advantage of emerging technologies (Laser Hardening) and components (Heavy Load Low Friction Bearings, High Chrome Rolls, Air Oil or Grease lubrication systems, maintenance free components, ….).

Our solutions provide an opportunity to improved performance, strength, speed, reliability to operate levellers in a cost-saving prospective.

All projects are custom-made and new components full interchangeable with the original ones, pass line, assembly dimensions, and pre-existing working parameters will be guaranteed as original or even better.

Every component is qualified and guaranteed for quick and smooth installation.

Reverse engineering is also offered to our customers who don’t have any sketch/drawing of existing obsolete machines and components.

Reverse engineering of components is handled with the expertise of our engineers using instruments, technology, and available equipment to guarantee a successful project.

For critical items (like heavy assemblies or components that cannot leave the production facility) the reverse engineering can be carried out direct from our technical staff to the customer site. All necessary measuring instruments will be delivered at site from BSA.