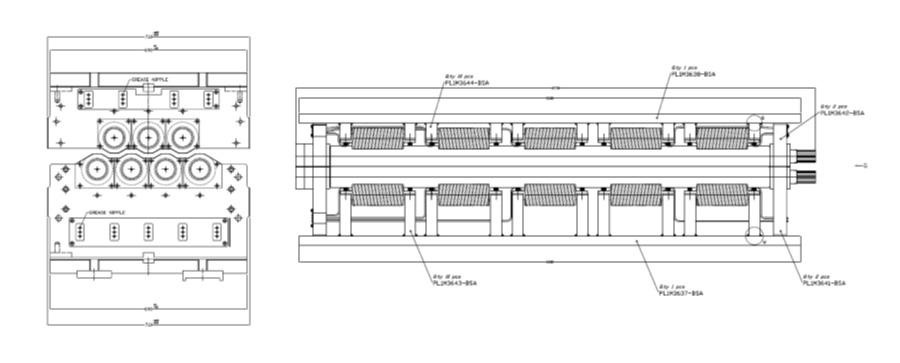

BSA is specialized in the production of all different types of work rolls for levelers and straighteners, 100% fully interchangeable with original OEMs components.

We use only selected forged material, quenched and tempered, with Chromium - Molybdenum – Vanadium inside, so to achieve the best microstructure and mechanical properties combined with the most suitable heat treatment.

Chromium coating, superfinishing and other type of finishing can be done accordingly to request.

The continue technology progress and the great accuracy of the grinding steps and the high surface hardness of the work rolls allow the customer to get strips with a high degree of precision and a very high surface finishing.

BSA makes the experience acquired on the field of the heat treatments available to all customers suggesting the best solution (material, hardness, hardness layer, roughness..) to be tailor-made accordingly their production needs.

The below characteristics are the most important ones to guarantee the good performance of the leveler during production and a long lifetime of your rolls:

- Good material with fine carbides, Q&T, US tested, optimal mechanical characteristic

- Uniform induction heat treatment

- Correct surface hardness accordingly to lamination process needs and type of roll

- Suitable induction hardened layer to guarantee lifetime of roll

- Out of roundness and straightness within 0.020 mm max.

- Surface free from marks (helicoid grinding marks, dots, grinding burn/cracks, etc. ).

- Fine Ra without surface defects, mirror finishing

- Concentricity between roll barrel and journals

- All the same diameter for the full set of rolls

Main application fields

- Pickling Line: Straightener - Scale Breakers

- Galvanizing Lines: Straightener - Tension Levelers

- Tinning Lines: Tension Levelers

- Cut to Length Lines: Straighteners - Precision Levelers

- Coating Lines: Tension Levelers

- Blanking line: Straighteners - Precision Levelers