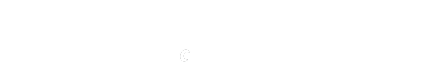

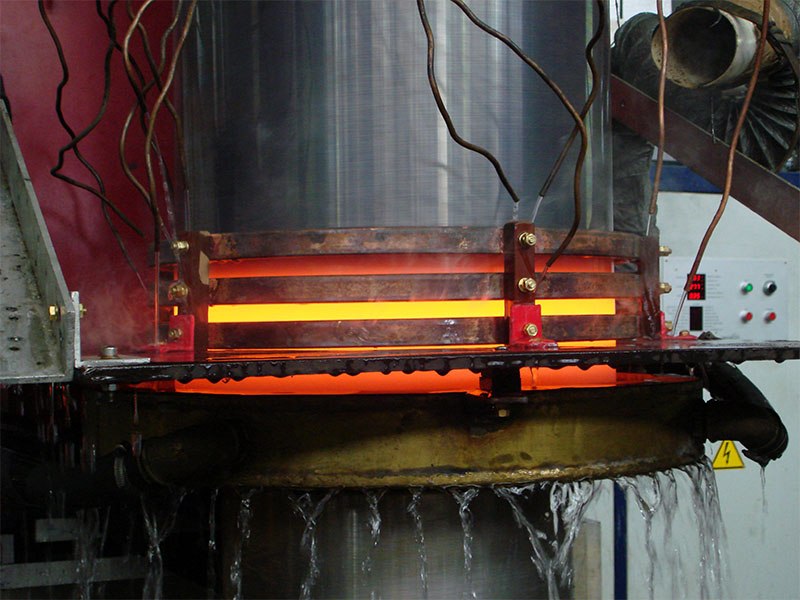

Heat treatment of all parts is carried out in our controlled companies TERMOSTAHL and TECNO TEMRANOVA LECCHESE (TTL) where more than 40 induction machines with over 15 Megawatt of total output power are in service.

There is large availability of high frequency, medium frequency and low frequency machines in order to control the hardening penetration from 1 to 30 mm in radius.

This allows to perform the best heating conditions and guarantees correct depth of hardness and absence of crack propagation.

All BSA products are 100% heat treated at our own facilities and checked after hardening; an inspection test is released at the end of the manufacturing cycle.

There is large availability of high frequency, medium frequency and low frequency machines in order to control the hardening penetration from 1 to 30 mm in radius.

This allows to perform the best heating conditions and guarantees correct depth of hardness and absence of crack propagation.

All BSA products are 100% heat treated at our own facilities and checked after hardening; an inspection test is released at the end of the manufacturing cycle.