As back-up rolls prevent work roll deflections, they perform a key function that helps to ensure proper performance of the entire levelling machine.

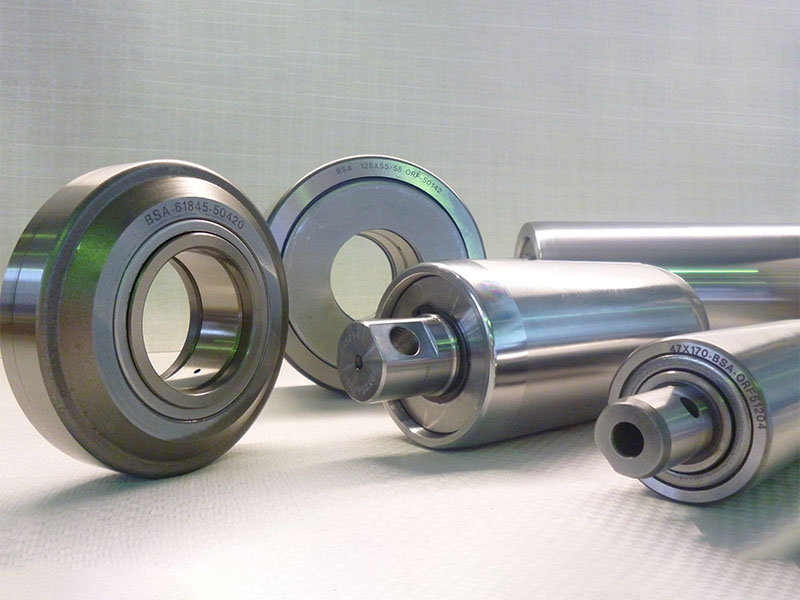

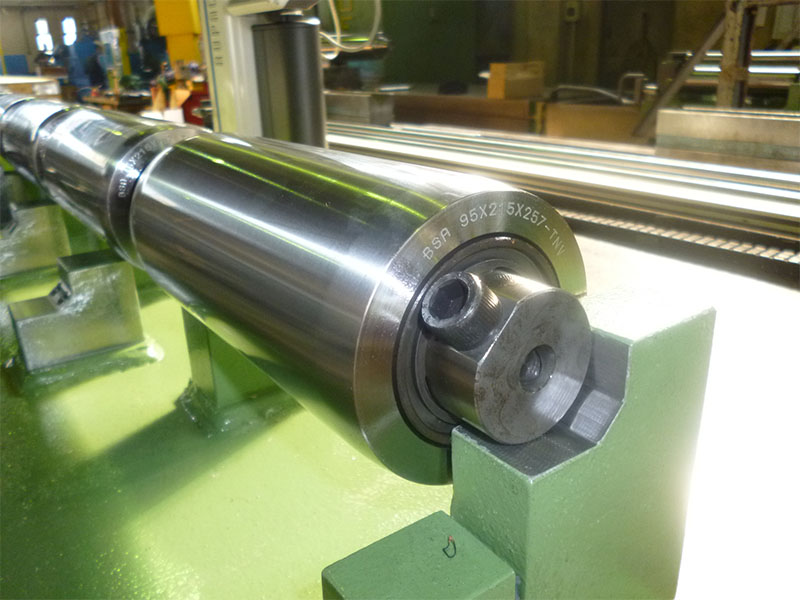

For this reason BSA became more and more specialised in the production of all the different types of backup roll bearings for levelers and straighteners.

There are several different backups configurations that can be produced. We can also customize the inner configuration to increase performances and lifetime for a more functional line.

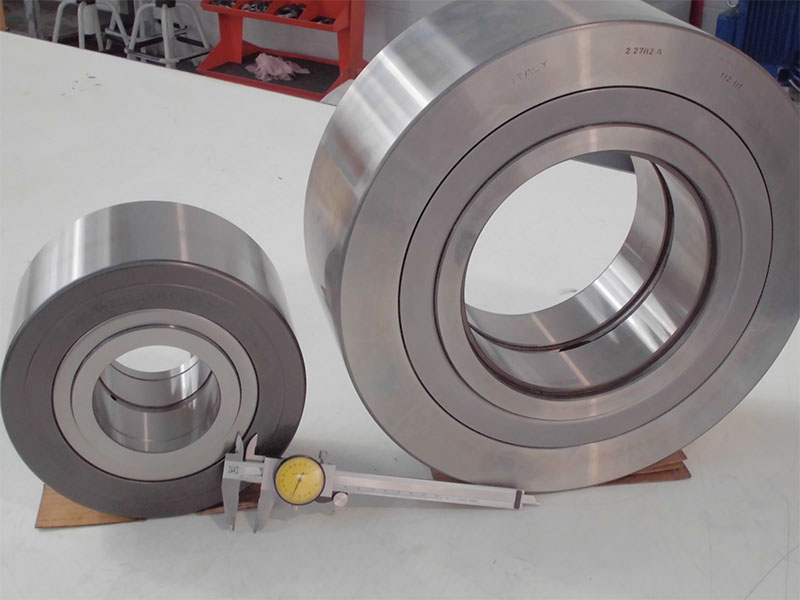

Our target is to propose to customers new technical solutions specific to their needs, goals and resources through new materials and treatment specification.

We can also upgrade the complete internal design to guarantee better radial and axial load capacity both static and dynamic, higher speed, better temperature resistance. All the inner parts are studied, designed and realised to improve performance, even the choice of lubricant type that is selected from top producer.

For this, we can choose among a wide variety of solutions for each type of bearing functionality, in order to reach a combination that results in optimum yield of high quality product, better resistance to ware and load, easy maintenance and longer lifetime.

Main application field

- Long life sealed bearings

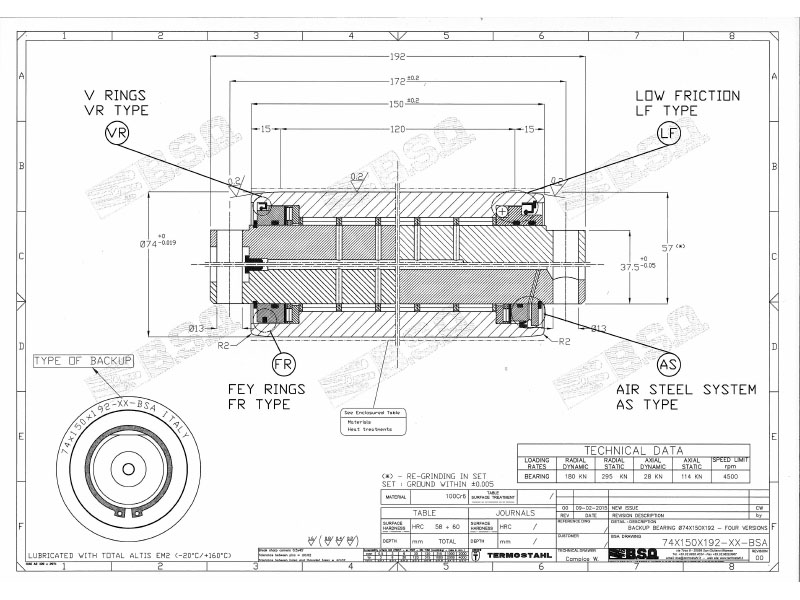

- Low friction bearings for Tension Levelers

- High speed bearings for Tension Levelers

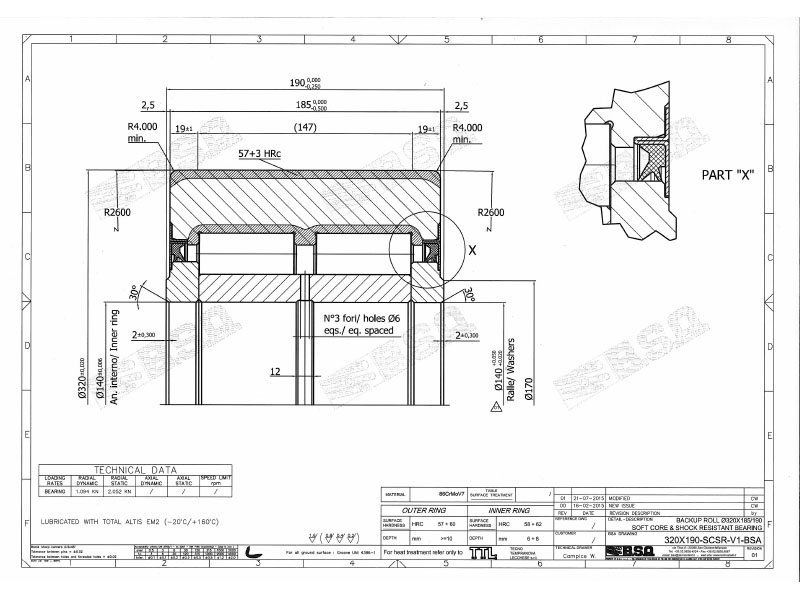

- Soft core & shock resistant bearings

- High load bearings for heavy duty Levelers